Bellows Operated Auto Guide

Purpose

In a paper machine there are several forming wires and felts, called fabrics in general, that function to support the paper being manufactured. These fabrics travel over networks of rolls in cyclical patterns. Since all of these rolls cannot be exactly level and aligned with each other, devices are needed to keep the fabrics running properly in the centre of the rolls. These devices, together called a guiding system, function to keep each fabric running in the centre of the rolls of the paper machine.

A Wire and Felt Guiding System is composed of mechanical devices used to keep the fabric running properly in the centre of the rolls over which it travels. This is done by pivoting one end of the guide roll in the proper direction to correct the errant fabric travel.

H & T Proportional Bellows Auto Guide avoids damage to wire or felt caused by their cross-directional movements, over running or pre-mature creasing and the resultant loss of production. An auto guide is the most convenient, reliable and economical device using mill's normal air supply for its auto operation.

Principle of Guiding

The guiding of fabrics is based on the principle that the fabric will always leave a roll perpendicular to its rotational axis. This is governed by the direction of fabric travel. This dictates that the fabric will always travel toward the end of the roll it encounters first. Hence the guide roll is automatically moved to change the fabric travel.

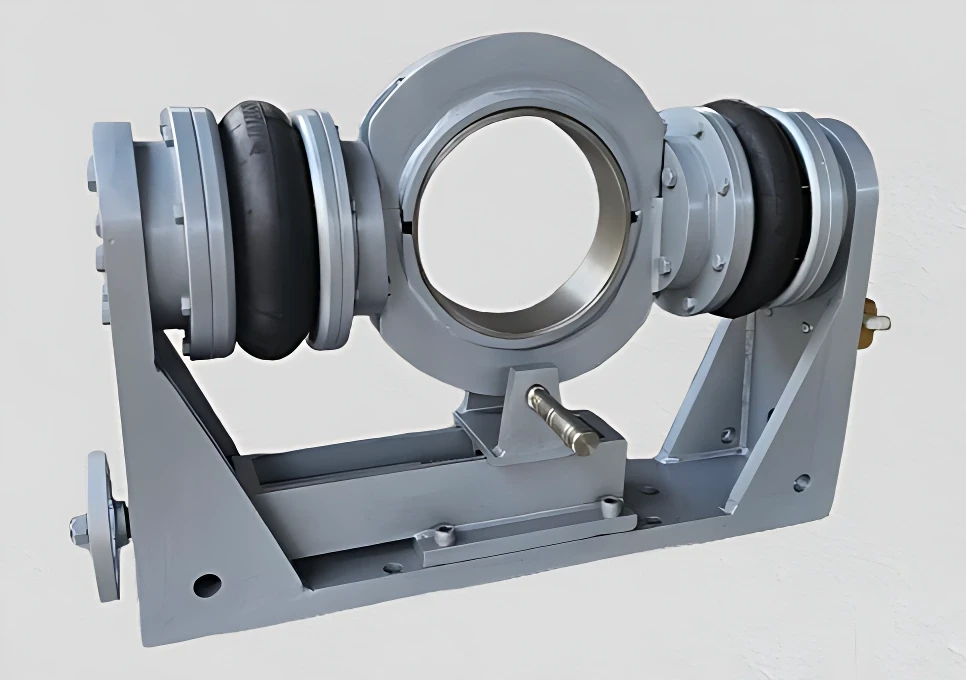

Design

H & T Wire and Felt Guide consist mainly of a pneumatically operated automatic guide and guide sensor to control the movement of the guide. The guide holds the bearing housing of one end of a roll and moves it back and forth using air-pressurized rubber air bellows. The guide sensor is a control device for the guide and regulates the air flow to each of the guide bellows.

When triggered appropriately, the rubber bellows swivel the guide roll, mounted on-site on the positioning unit, in one or the other direction respectively.

An edge sensing device is required to control the guide that continuously monitors the fabric run that minimize fabric wear by avoiding fabric run-off. It determines the actual position of the fabric and specifies its target position. The one supplied along is the contacting pneumatic type palm assembly.

MODELS

|

WIRE/FELT/SCREEN RANGE |

TYPE |

|

Upto 3000 mm wide |

80-160/60 |

|

From 3000 to 3800 mm |

140-200/65 |

|

Over 3800 mm wide upto 4500 mm |

160-250/70 |

|

Guide Roll bearing housing bracket |

Cast Steel / Stainless Steel |

|

Tracer unit ( Palm Assembly ) |

Body in Aluminium / Stainless Steel |

|

Internal Assembly |

Bronze and Stainless Steel |

|

Sensor Palm |

Stainless Steel with ceramic insert / Stainless Steel Rotating Roller |

|

Stand for Palm |

SS-304 |

Guide Positioning

θ = 20º for Wire or 30º for Felt

x = Lead in distance should be 2/3W

y = Lead out distance should be 1/3W

W= Width of wire/felt

PNEUMATIC CONNECTIONS

VR - Volume Control Valve

R - Air Regulator

F - Air Filter

SV - Shut off valve

DV - Drain Valve

W - Wire/felt/screen

P - Palm

SYSTEM ADVANTAGES

-

Maintaining a straight fabric run with minimum fabric oscillation

-

Avoid fabric run-off

-

Minimize fabric edge wear

-

Reduce sheet breaks

-

Optimize Paper Productivity

DESIGN ADVANTAGES

-

Well proven reliable design

-

Easy installation and zero maintenance

-

Efficient and prompt after-sale service by competent engineers/technicians

-

Highest tracking accuracy for most demanding applications

-

Proportional and accurate response

-

Low air consumption

Related Product

Auto Wire Tensioner

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

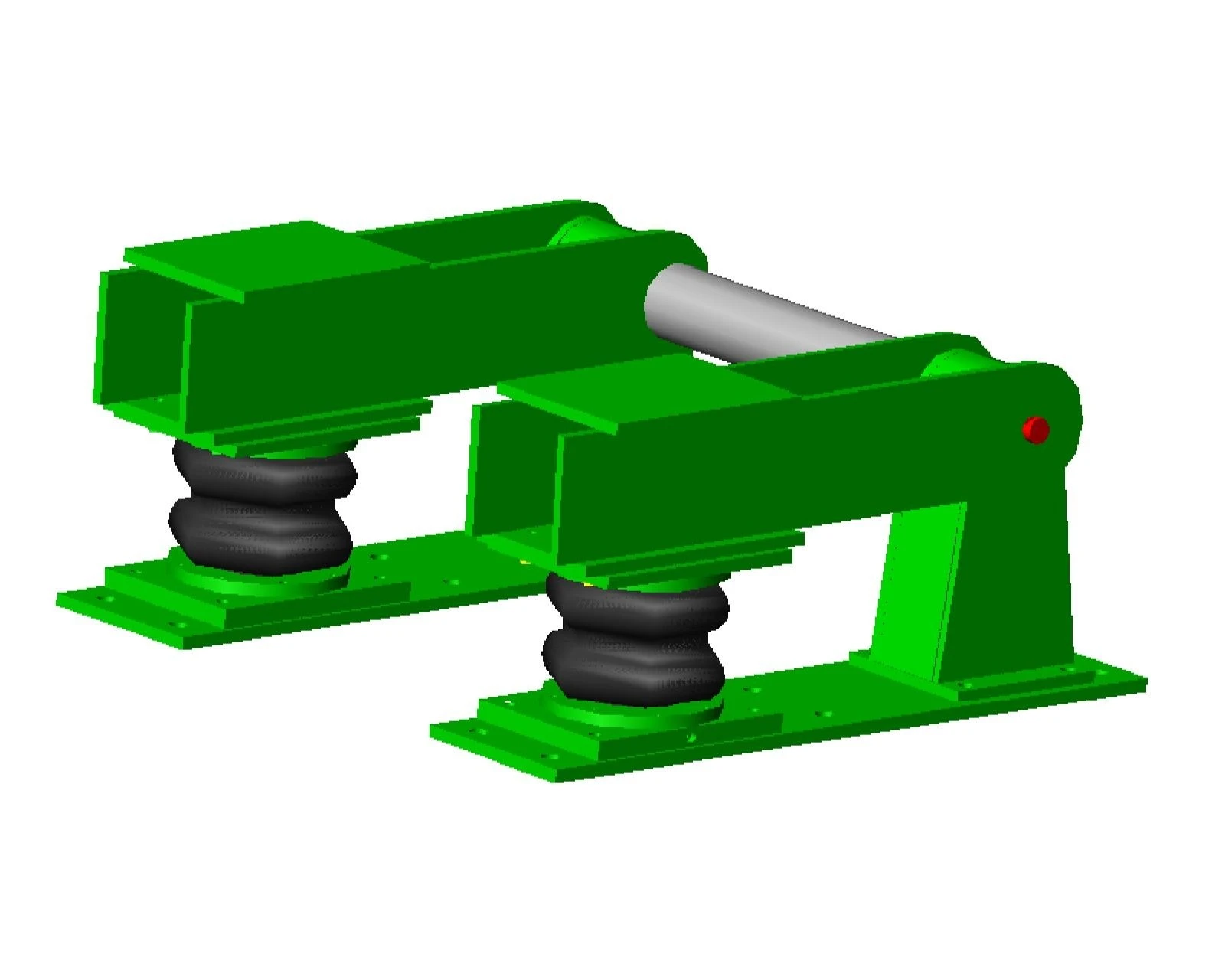

Double Felt Stretchers

These stretchers have been specially designed for long felts especially in duplex machine. Stretching achieved is four times the roll travel.

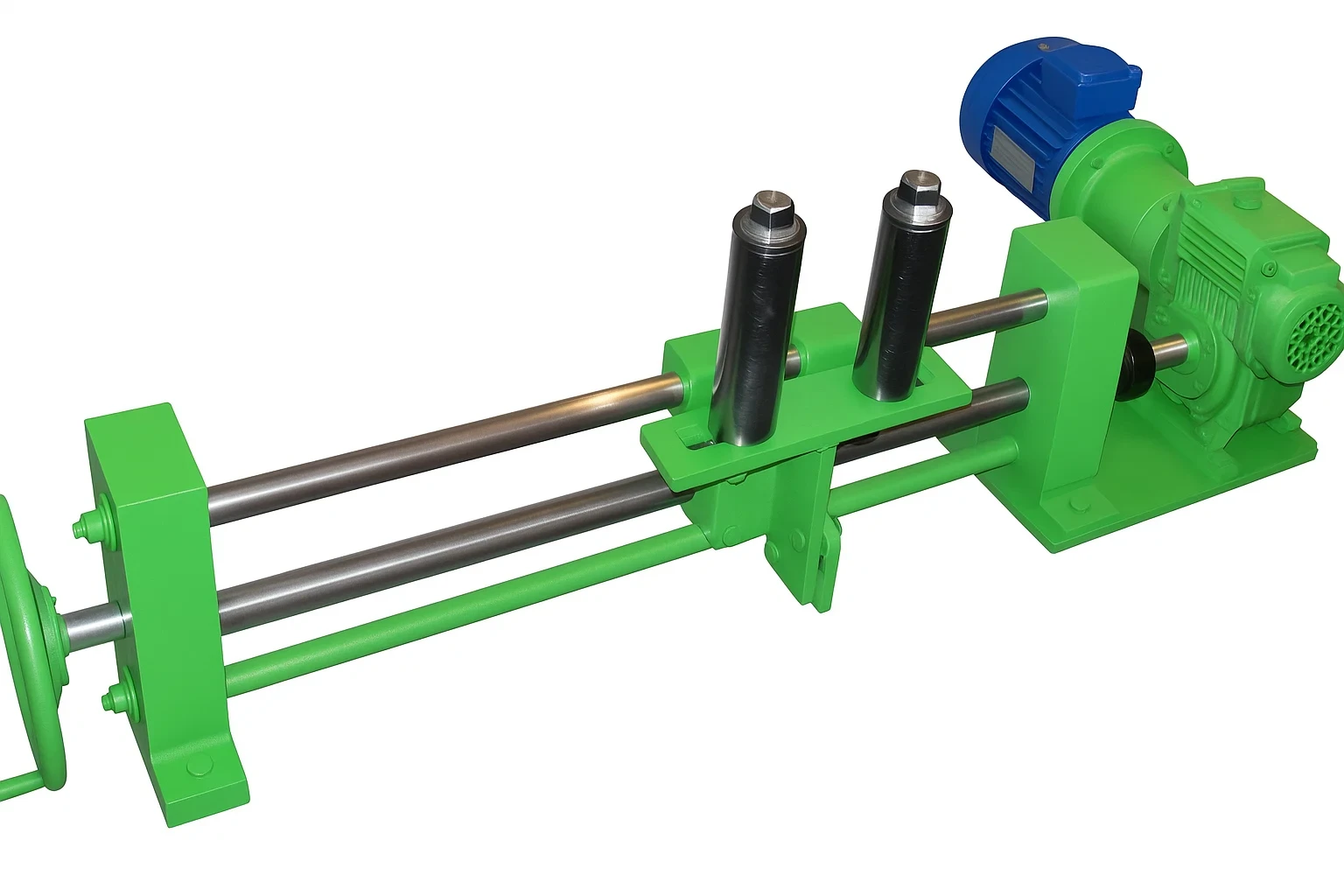

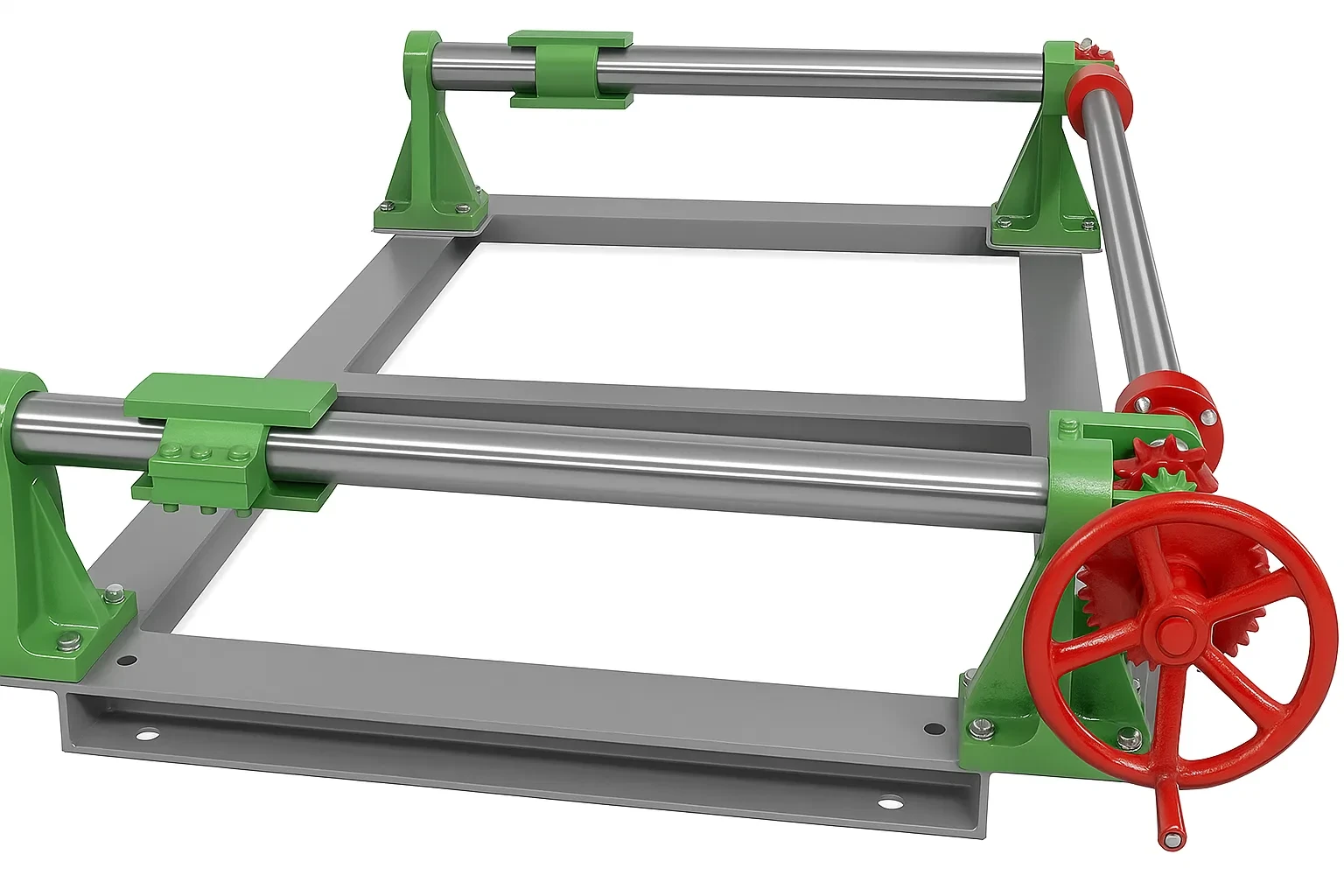

Electromechanical Belt Shifter

H & T Electro Mechanical Belt Shifter is normally used to shift belt over cone pulley drive to match the draw speed between different section.