Starch Spray System

Purpose

The starch spray system is designed as an answer to improve the bursting factor of paper. Indian paper mills, kraft paper mills and corrugated containers manufacturers have traditionally had access to inexpensive virgin fiber that could be mixed with hardwood or softwood to reach required strength. That has changed in recent years, with increasing dependence on recycled fiber sources, especially for liner board and medium grades.

However, as the fibers are recycled, they get shorter and weaker which results in a lower grade product with less final sheet strength. Synthetic additives to enhance product strength have often been prohibitively expensive in a marketplace where profit margins have been ravaged by declining paper prices.

Now, a cost-effective starch spray solution has emerged in India that is designed to boost paper strength (up to 100% in IGT, 25% in Concora, and 20% in CFC and Mullen) while cutting fiber use by replacing much of the fiber with starch.

Principle of system

Essentially, special spray nozzles apply an unmodified starch suspension to the fiber web of paper products to increase their internal strength and improve their surface properties. The starch stays internally on formed sheets and gelatinizes while drying. In its starch spraying system, process water mixes with starch to create slurry that flows into a run tank, which is sprayed onto the sheet former.

The process of starch spray is based on the principle that the starch solution is sprayed through a spray bar installed at a place over the wire section where it discharges starch over the paper and maximum retention of starch takes place so that maximum benefits of system are gained and bursting factor of the paper gets improved.

It is the point where dryness of the paper just starts i.e. just after the last hydro foils and at the starting of first vacuum box. This is the point where maximum retention of starch takes place upto 80%. Solution used is generally 30gpl. However, it may change according to process requirements.

Design

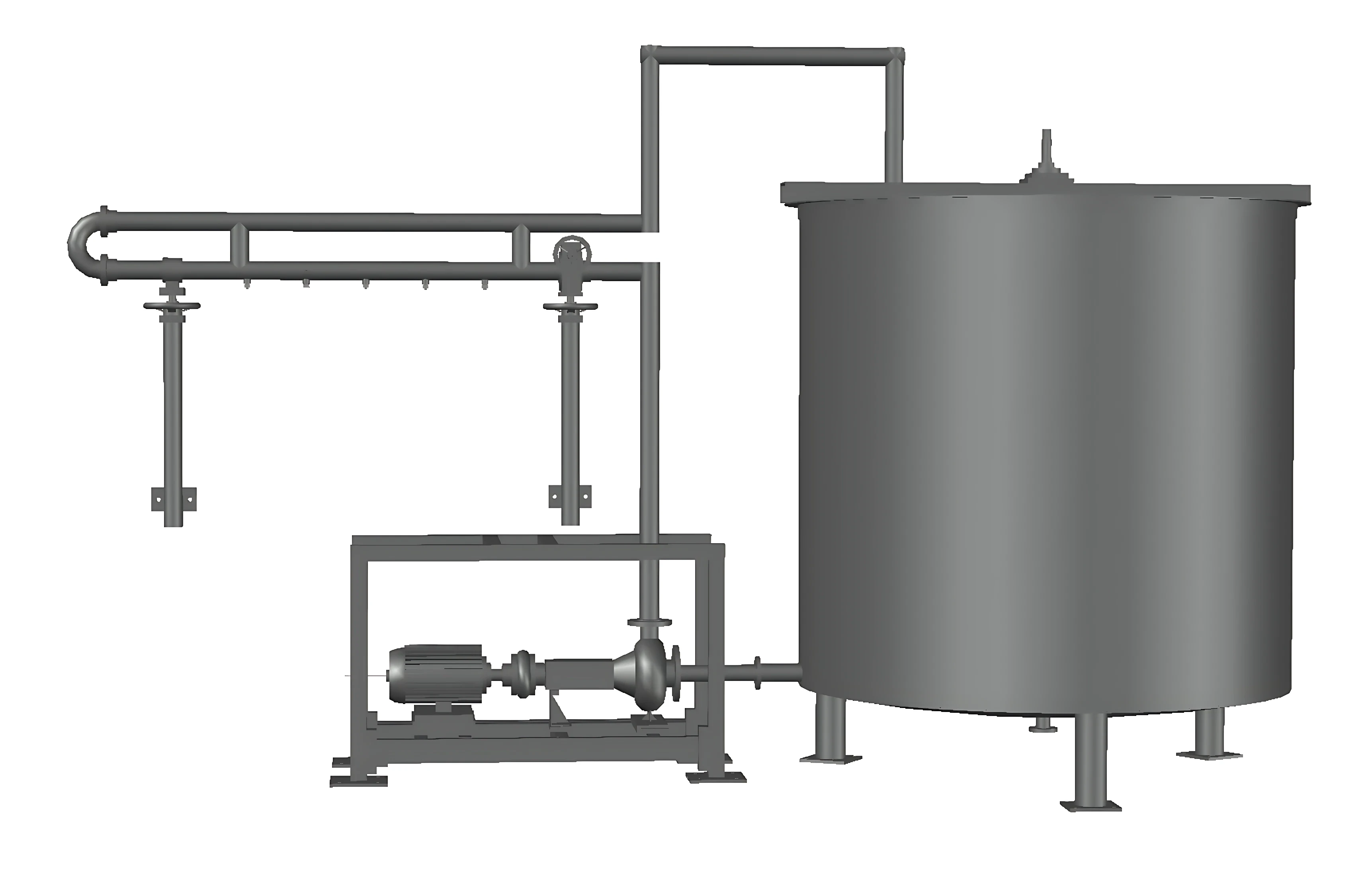

H & T Starch Spray System consists mainly of a two tanks for preparation of starch. Starch solution is then transferred to nozzles attached on a shower pipe over the machine through end suction centrifugal pump operated by a motor. The starch solution also passes through stainless steel Duplex water filter. There is also provision to add fresh water and to bypass the excess starch solution back to tank in case not in use or according to process requirement by use of different two-way and three-way valves.

Tanks: Preparation and Service Tank along with Agitator and Motor.

Pump: End Suction Centrifugal Pump.

Motor: 10 HP, 3-phase, Frequency 50 or 60 Hz.

Filters: SS 304 Duplex Quick Release Filters

Spray Pipe: With Fish tail nozzles to cover complete Paper width or Mould width

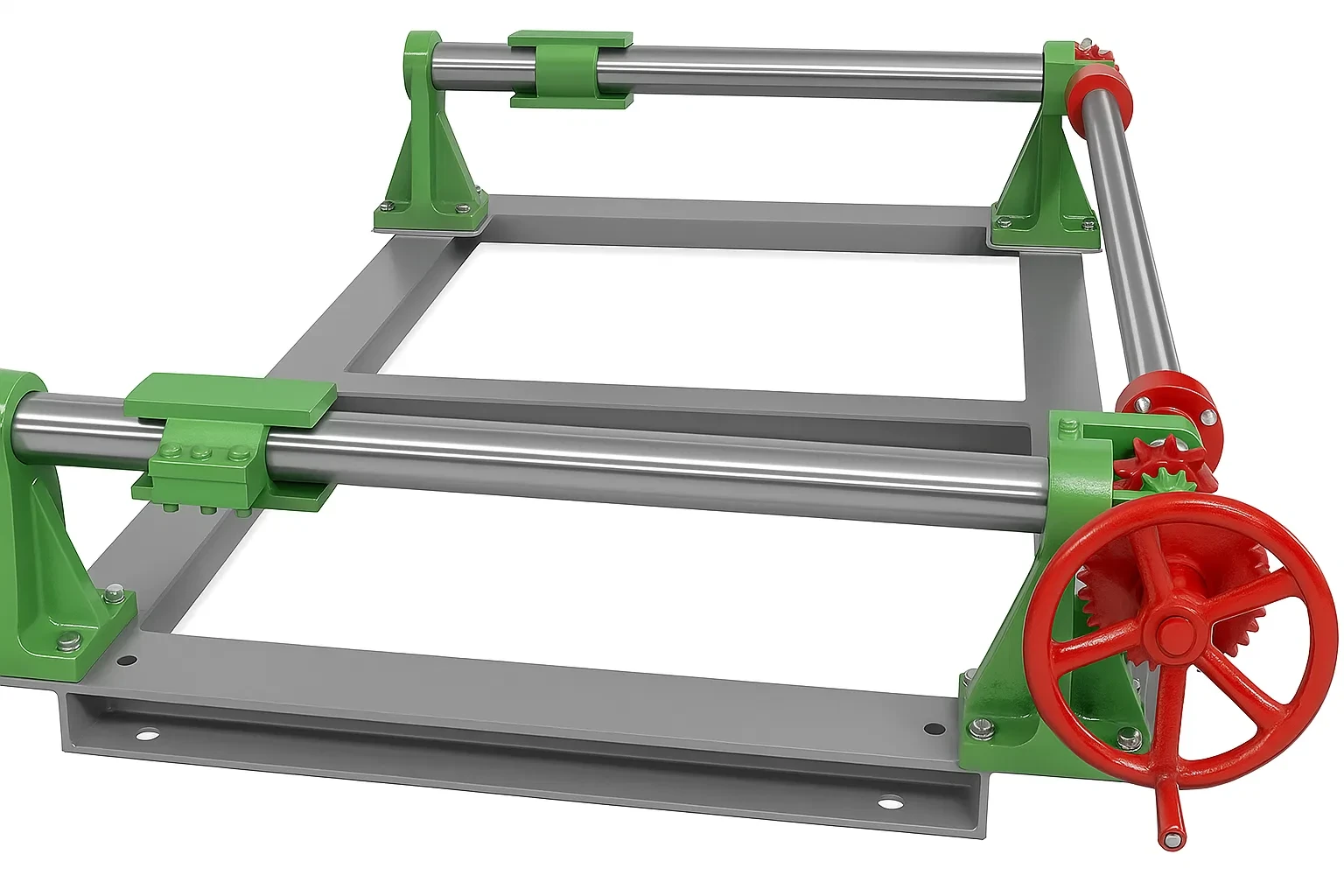

Linear, Angular & Vertical Positioner: Positioners ensure spray at the correct point so that maximum benefits can be achieved.

Angular movement is caused by a gear box.

Vertical Movement is caused by a wheel through spindle and nut.

Horizontal Movement along the machine direction is through a slotted channel.

Related Product

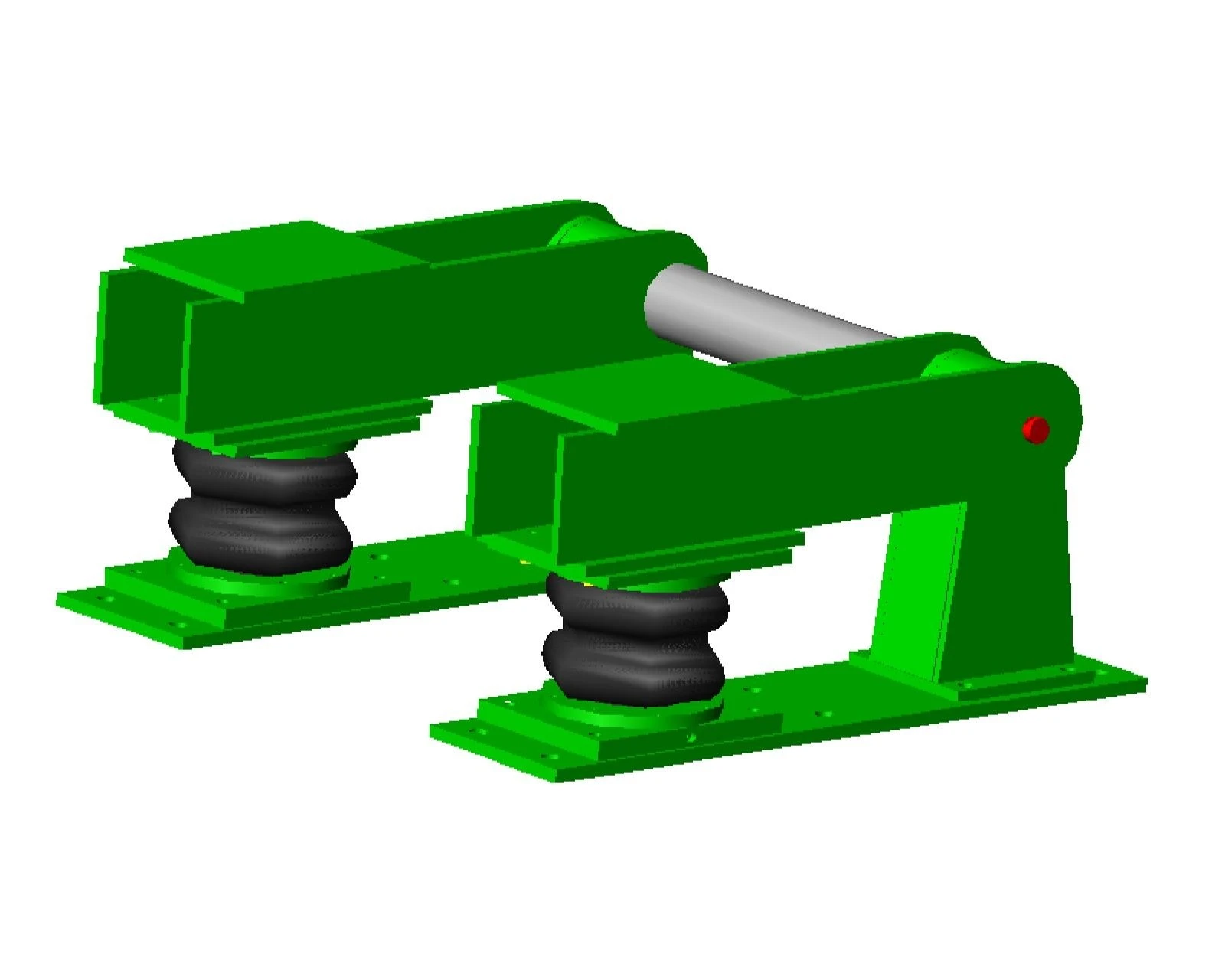

Auto Wire Tensioner

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

Double Felt Stretchers

These stretchers have been specially designed for long felts especially in duplex machine. Stretching achieved is four times the roll travel.

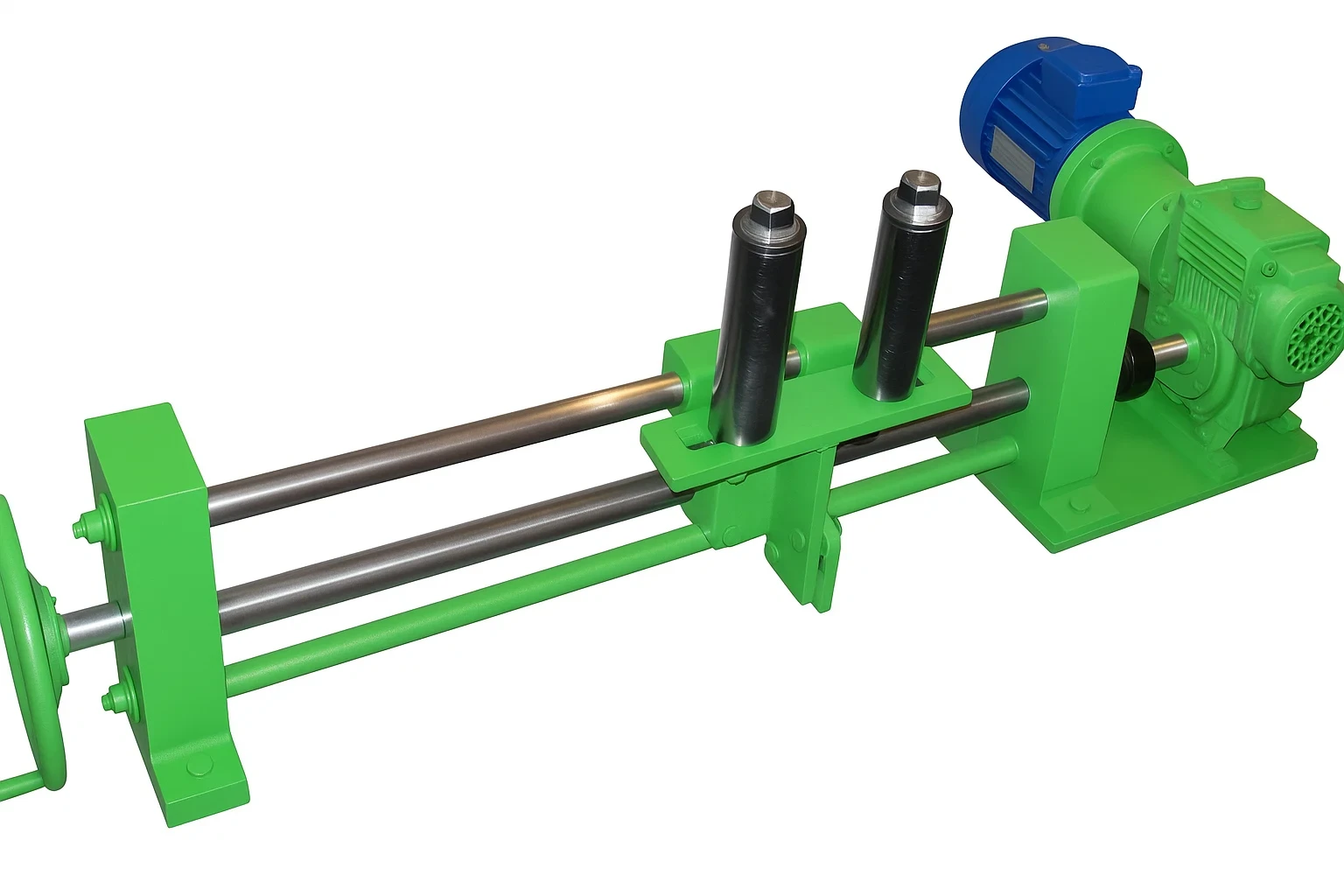

Electromechanical Belt Shifter

H & T Electro Mechanical Belt Shifter is normally used to shift belt over cone pulley drive to match the draw speed between different section.