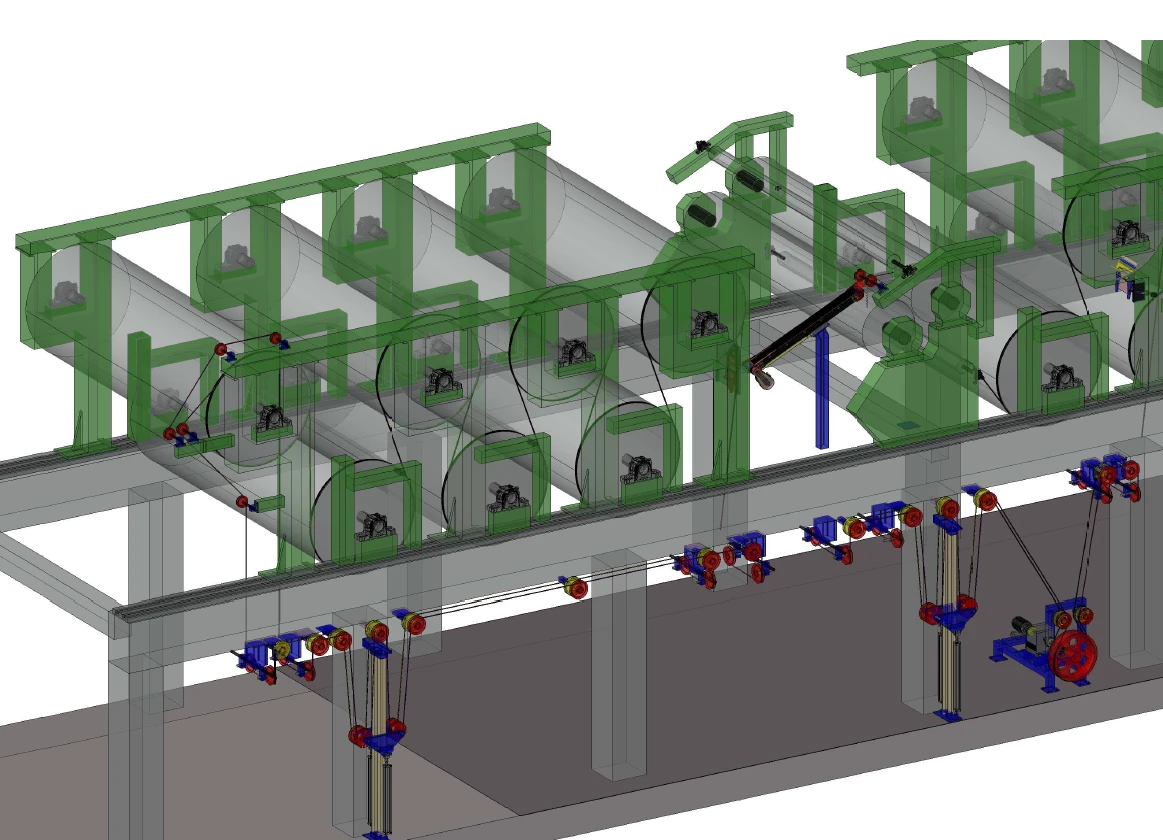

Rope Carrier Paper Tail Threading System

-

Primarily designed for ground floor machine but it can also be designed for first floor machines.

-

Easy to install and access.

-

Size variation according to number of dryers in a group. (Usually, there are 6-8 cylinders in a group).

-

Available in one, two and three ropes configurations.

-

Available in weight loading and pneumatic loading variants

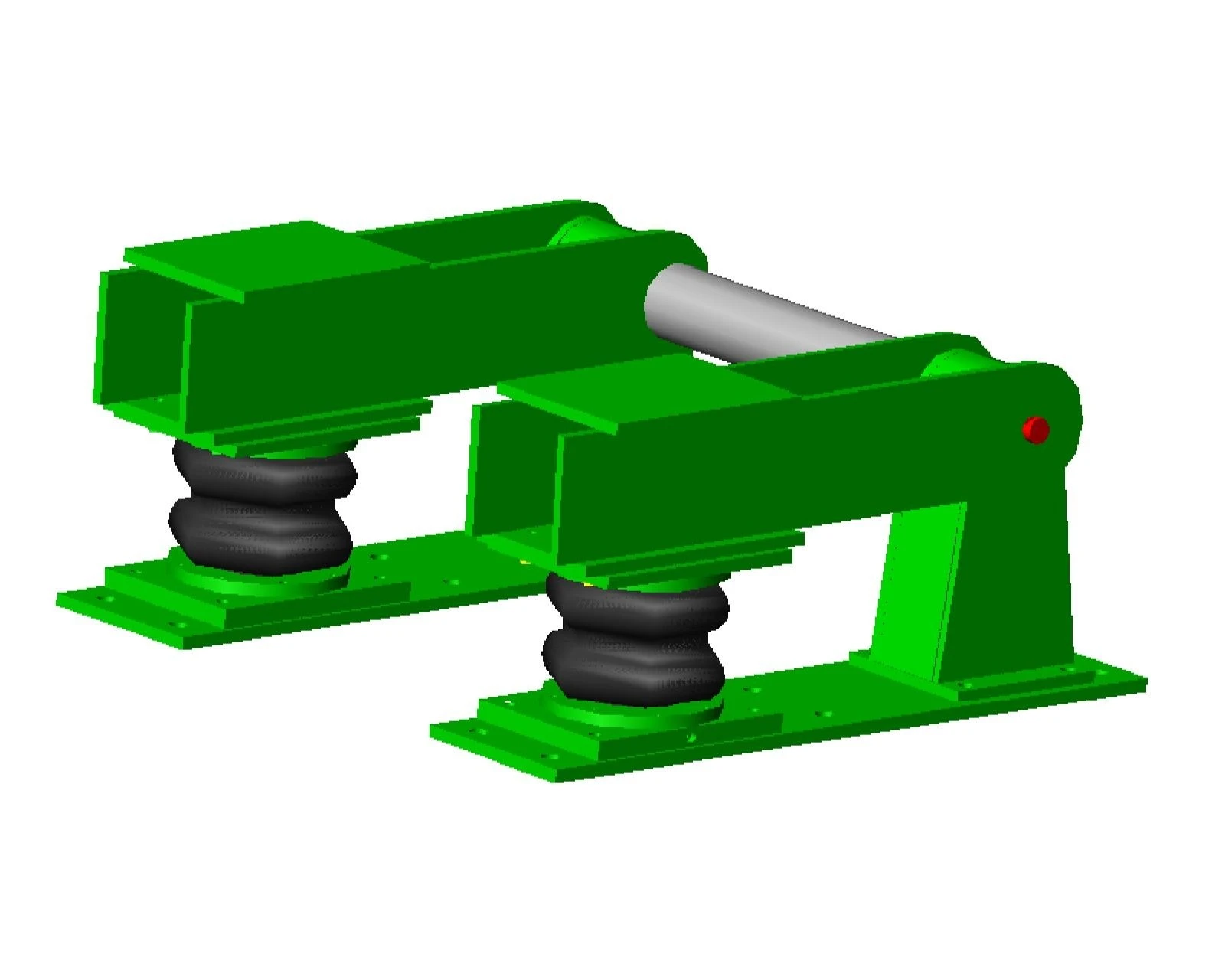

H & T Rope Carrier System with Vertical Stretcher

-

Vertical Stretchers are specially designed for first floor machines.

-

These Vertical Stretchers are being made available in both variants --Weight loading as well as pneumatic loading variants.

-

These can be installed in One, two and three Ropes configuration.

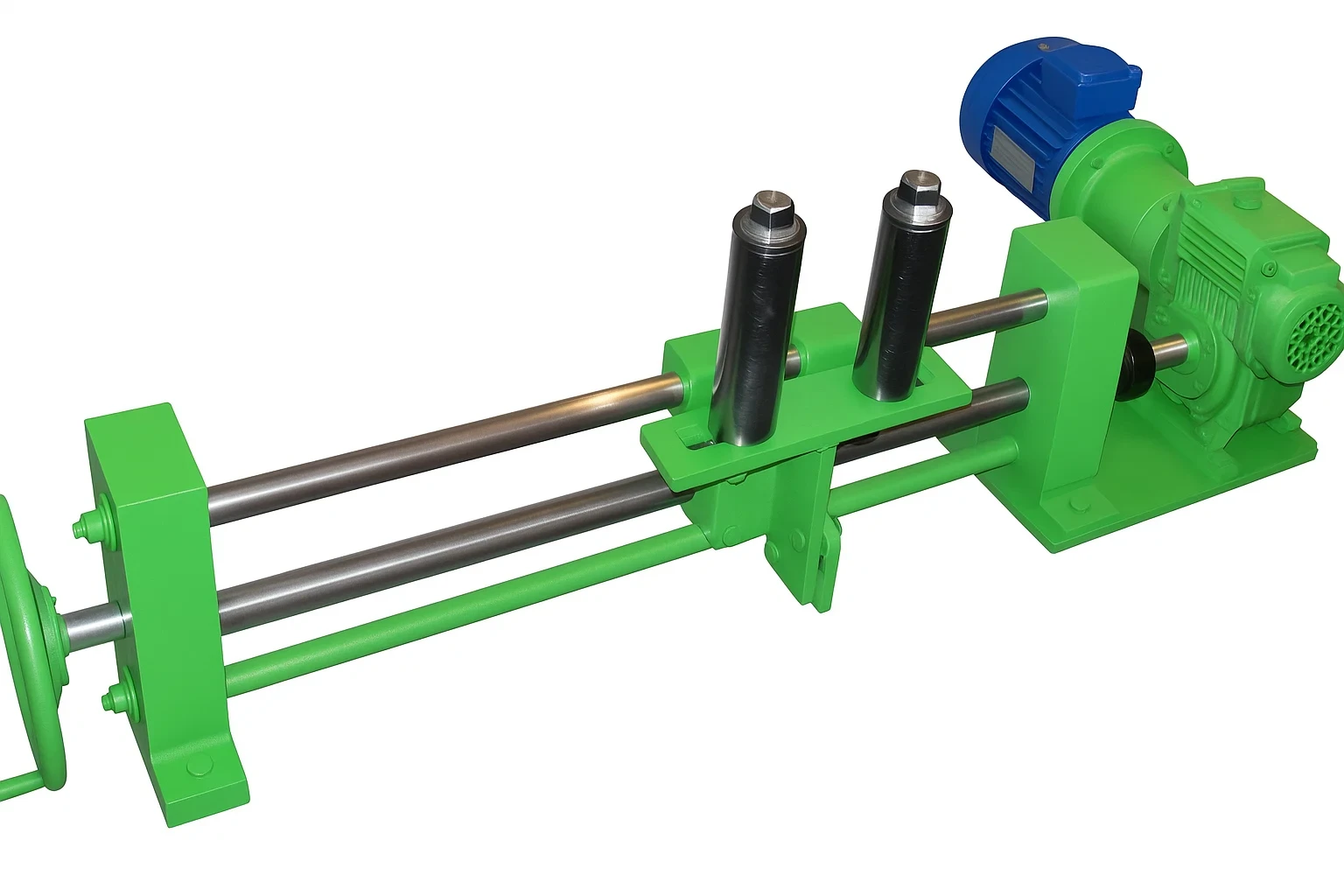

SEPERATE ROPE DRIVE

Rope Drive is normally taken through Dryer Cylinders but in few cases the rope drive is used to drive a set of ropes independent of the machine rolls or Dryer Cylinders:

-

Normally used in Coater, Size press and Pope reel sections however can also be used for Dryer Sections after installing Idler Pulleys over Dryer Cylinders.

-

Suitable for one, two and three ropes.

-

Requires a separate motor, gearbox and variable frequency drive.

-

A drive wheel that allows double rope wrap angle eliminates rope slippage.

-

Rolls are equipped with free wheeling sheaves.

-

Ropes are fully operated only during threading operation.

-

To extend rope life.

-

Synchronized with machine speed.

The rope system can be shut down when not in use. Extends life of the equipment and ropes. Ropes are not continuously running through contaminated process areas. The drive system is custom designed to meet the customer's needs and to compatible with the mills existing drive controls.

DRYER ROPE RINGS

One very commonly asked question is, “What if the dryer cylinders have no grooves for rope?”

This is very common scenario especially in old machines. However, we have a solution to it. H & T provides separate grooved rings as an answer to this situation. The grooved ring diameter is approximately the same size as cylinder diameter and can easily be mounted over the dryer cylinder face. The width of ring may vary from 50mm and above. For Mild Steel Cylinders the ring is directly welded to the face of the cylinder. For Cast Iron cylinders the ring is mounted to the face of the cylinder through bolts and mounting blocks provided with ring.

The only constraint associated with such installation is the space required between the dryer face and the machine frame should be 15mm greater than the grooved ring width recommended.

Fabricated Dryer Rope Sheaves

-

Proven groove design in 2 or 3 rope profile, insures good rope grip for better tail carrying.

-

Custom designed for dryer cylinders and reel drums in sizes from 36" to 60" diameter.

-

Can be directly welded to Mild Steel Cylinders or bolted to Cast Iron Cylinders.

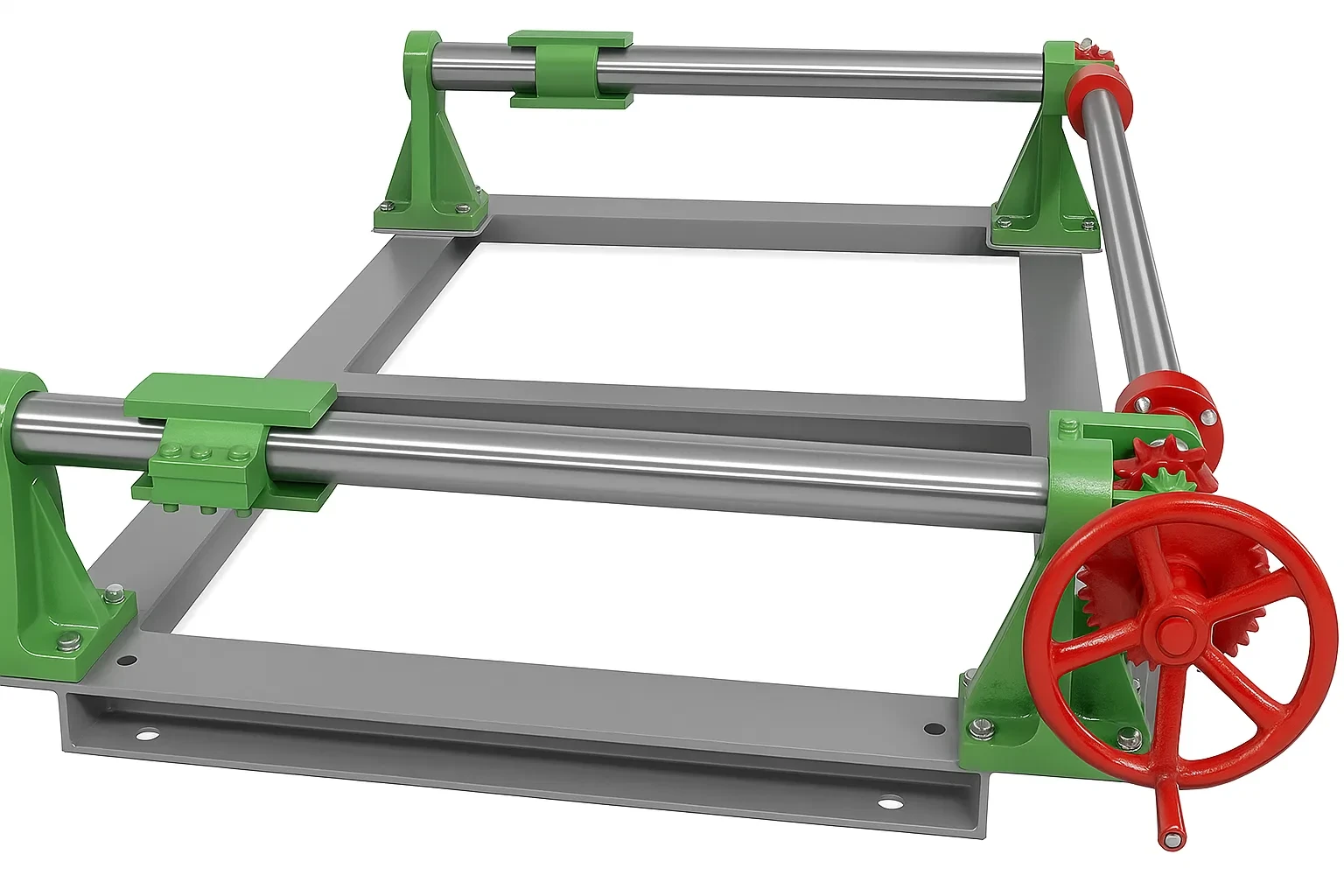

MOUNTING HARDWARE

We supply combination of Brackets, Shafts and Forks for pulley adjustment and proper rope alignment that ensures long rope life.

The material of construction is mild steel however can be changed to stainless steel for wet sections like coaters, size press and wet press on request.

FORKS:

For Mounting Pulley and gives freedom to rotate pulley by 360° degrees and allow for pulley centre adjustment

MOUNTING BRACKETS:

For Mounting Pulley in any direction.

STRAIGHT SHAFT:

For Pulley adjustment and giving 360° rotation of Pulleys

BACKING PLATES:

All parts are supplied with backing tapped plates that can be easily grouted into concrete or welded over steel frame members for easy mounting and removal of rope carrier parts.

Related Product

Auto Wire Tensioner

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

Double Felt Stretchers

These stretchers have been specially designed for long felts especially in duplex machine. Stretching achieved is four times the roll travel.

Electromechanical Belt Shifter

H & T Electro Mechanical Belt Shifter is normally used to shift belt over cone pulley drive to match the draw speed between different section.