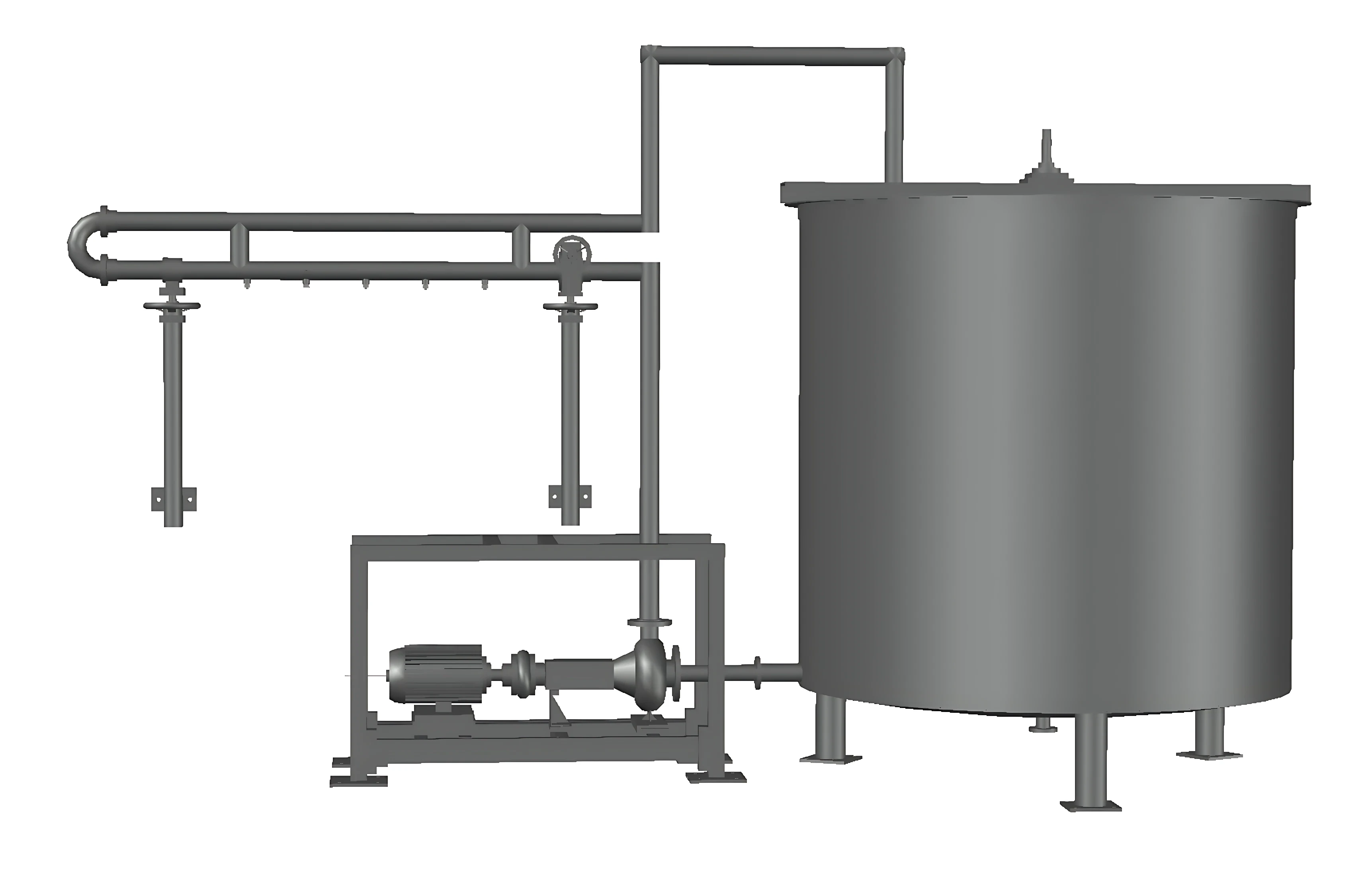

STATIONARY SHOWERS

|

Stationary Showers that is fabricated completely in Stainless Steel. These showers are put to various uses e.g. Fan jet showers for foam killing action in the head box, fish tail showers for cleaning the wire returning rolls etc. besides, the stationary showers offered by us can be availed at the most affordable prices. Applications:

|

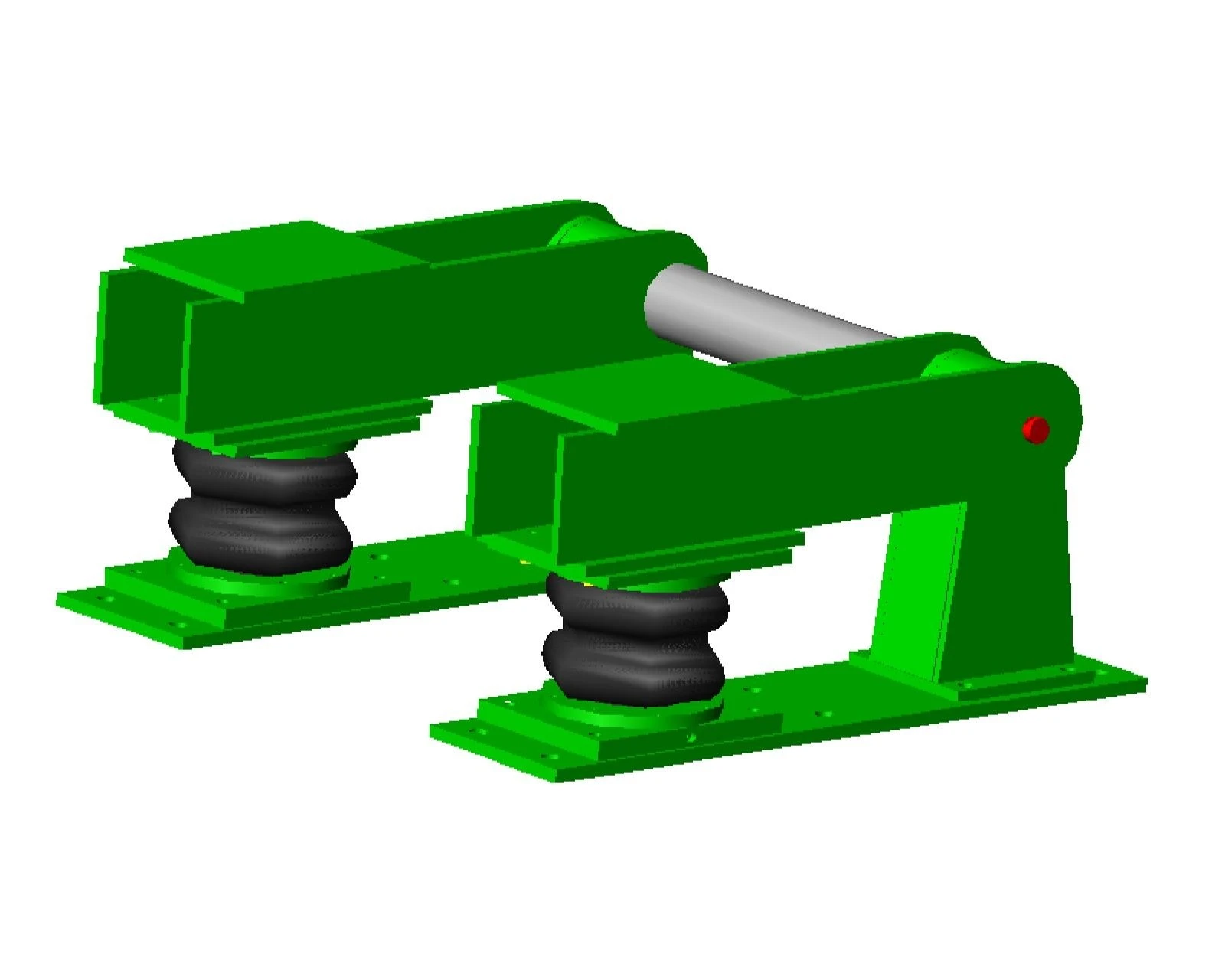

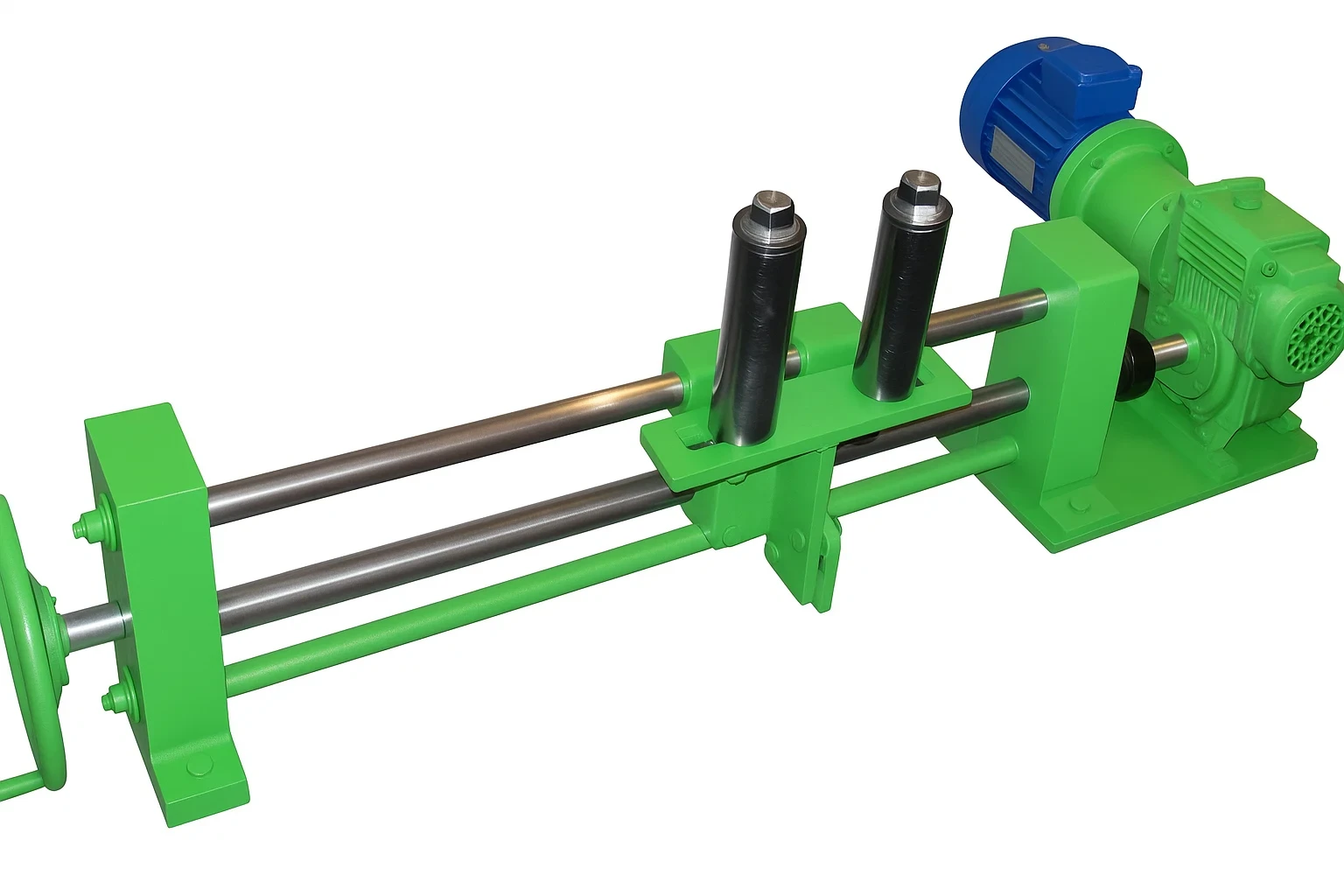

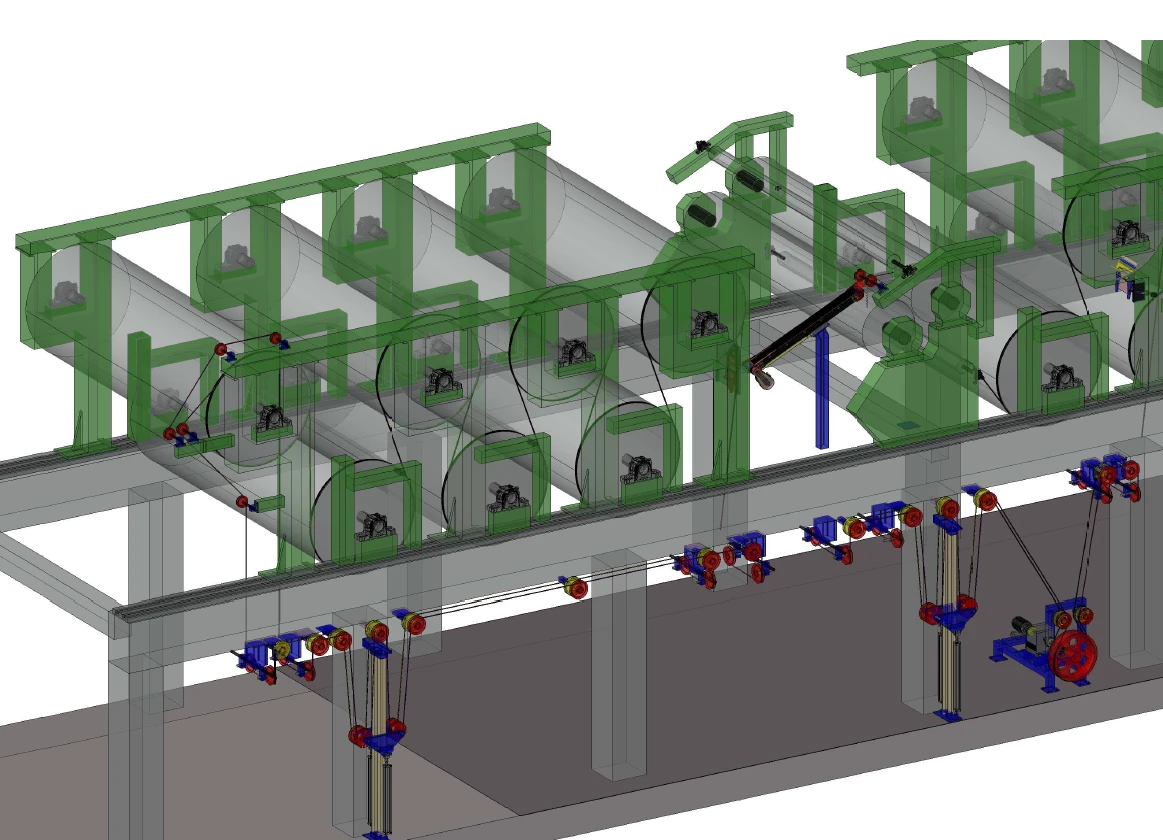

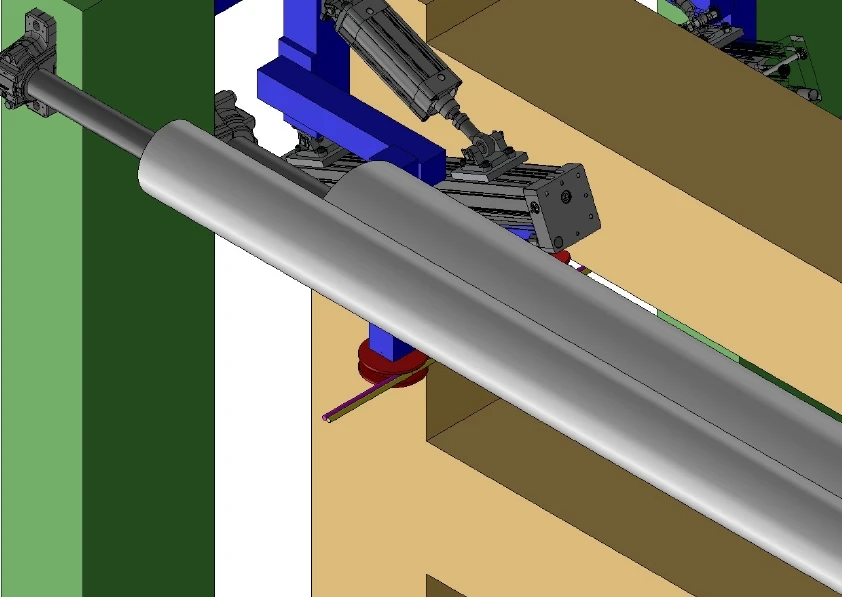

HIGH PRESSURE OSCILLATING NEEDLE JET SHOWER

We are a prominent manufacturer of a wide array of Oscillating Showers that is highly in demand in the market. These are very high pressure showers being used for cleaning felt or wire so that smooth running of the machine can be ascertained. The oscillation is provided either by pneumatic or electro-mechanical method.

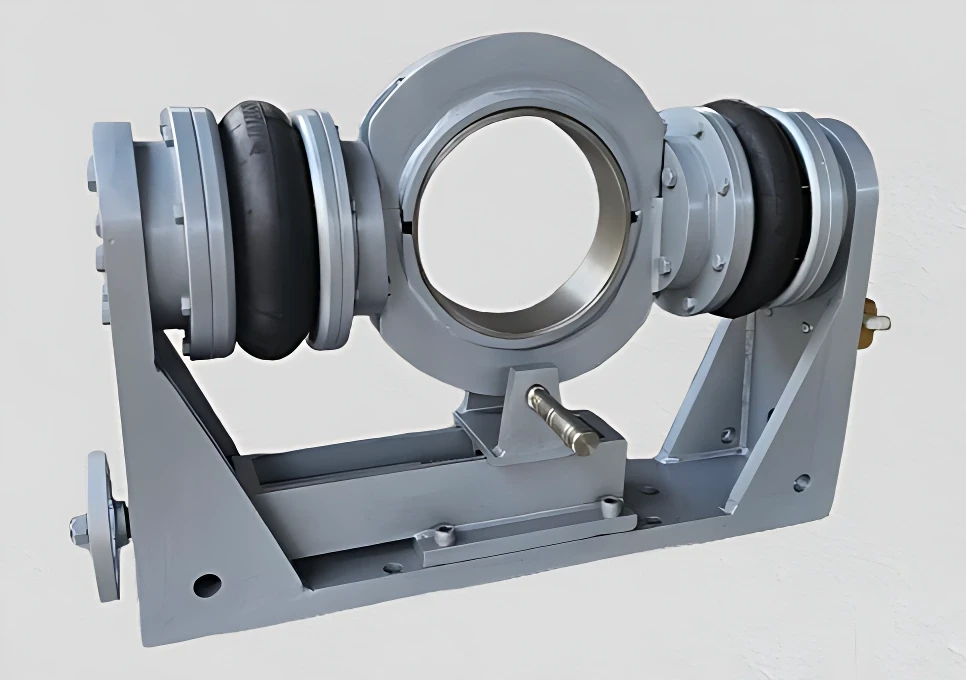

ELECTRO-MECHANICAL DRIVE

In this type of shower, oscillation is provided by a geared electric motor, crank and shaft drive. The stroke length of the shower is 110-1 50mm, but can be changed. Minimum number of oscillations is 20 per minute but can be more if needed. Crank & shaft drive are usually covered with M.S. sheet but can be supplied in S.S. if desired. Shaft is supported on brass roller. The standard distance between two nozzles has been kept at 100 mm.

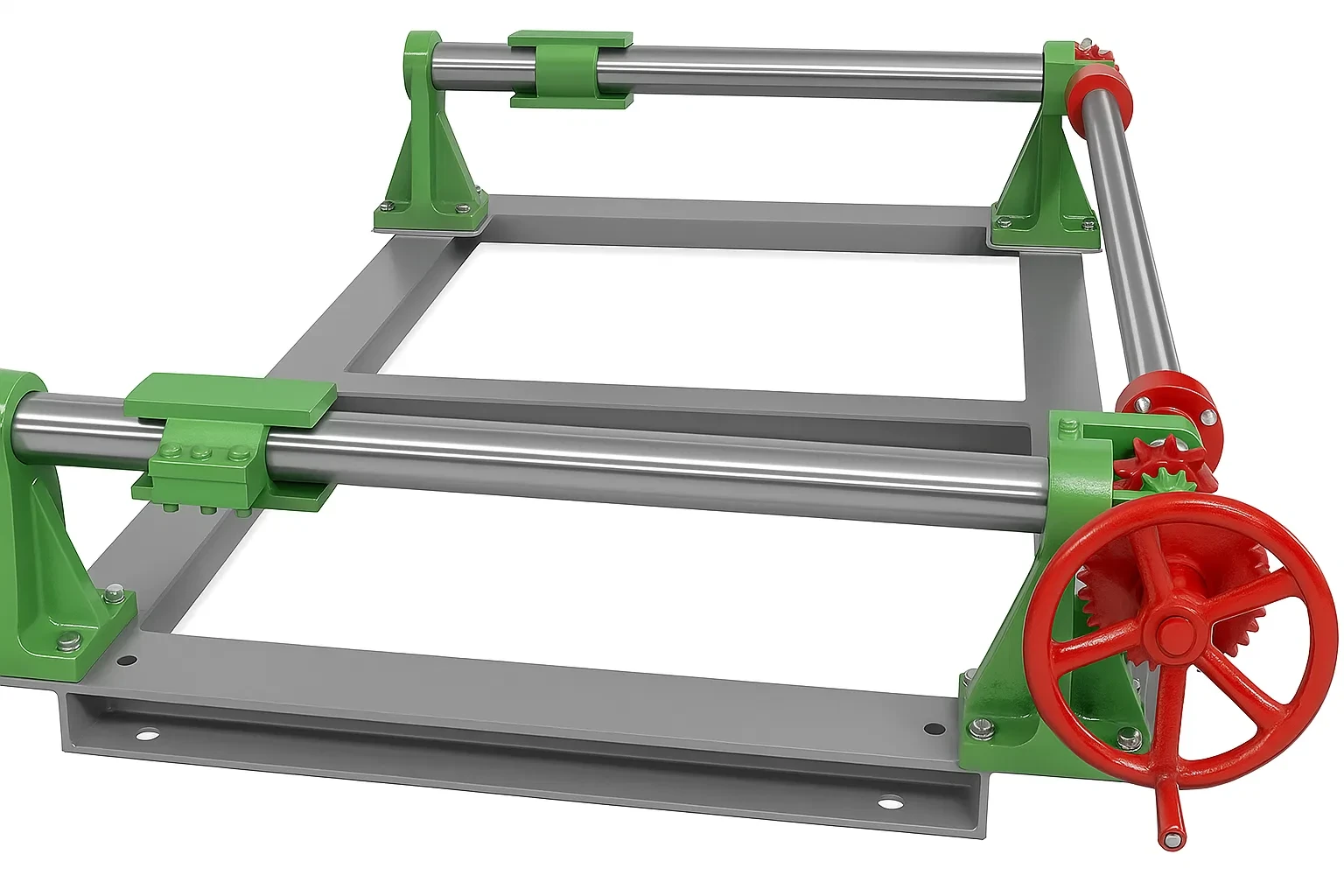

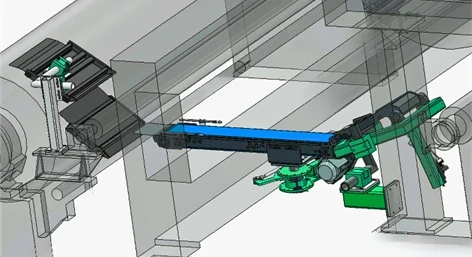

MICRO-TRAVEL DRIVE

For meticulous, uniform cleaning of the entire area of the felt or wire H & T offers its top-most model MICRO TRAVEL NEEDLE JET SHOWER. It does its cleaning operation with unmatched thoroughness. High Pressure oscillating showers of traditional design tend to leave diamond shapes of cleaned/un-cleaned and over cleaned portions on the felt or wire. However, micro-travel Mechanism of this shower eliminates this inherent weakness and ensures that uniformly spaced nozzles cover the area between any two of them by travelling at predetermined suitable speed depending upon machine's speed. This micro-travel to and fro movement is caused by an electric double geared motor and crank drive. The standard distance between two nozzles has been kept at 1OOmm, but can be reduced - if so desired by the customer. However, pump of higher capacity would be needed to maintain same pressure for greater number of nozzles. With micro travel drive, the supplied dome shaped needle jet nozzles have nylon brush to keep the nozzles clean. The brush is to be rotated manually to clean the nozzle as and when required.

Material:

- Shower Bar in SS 304/ SS 316

- Oscillator with Geared Drive

- Fresh Water Filter in SS 304/SS 316

- Shower Mounting Brackets in SS304/SS 316 with Brass Rollers

Edge Cutter Nozzle

Avail from us an immaculate gamut of Edge Cutter Nozzles that are designed in compliance with the highest international standards. These nozzles generate extremely fine (usually 0.5 mm) pencil of water of very high pressure which cuts through the paper edges very neatly. With a view to avoid choking of the fine-holed disk, a filter is built into the nozzle to filter out all dust particles out of water.

Material

-

SS-304/ SS -316